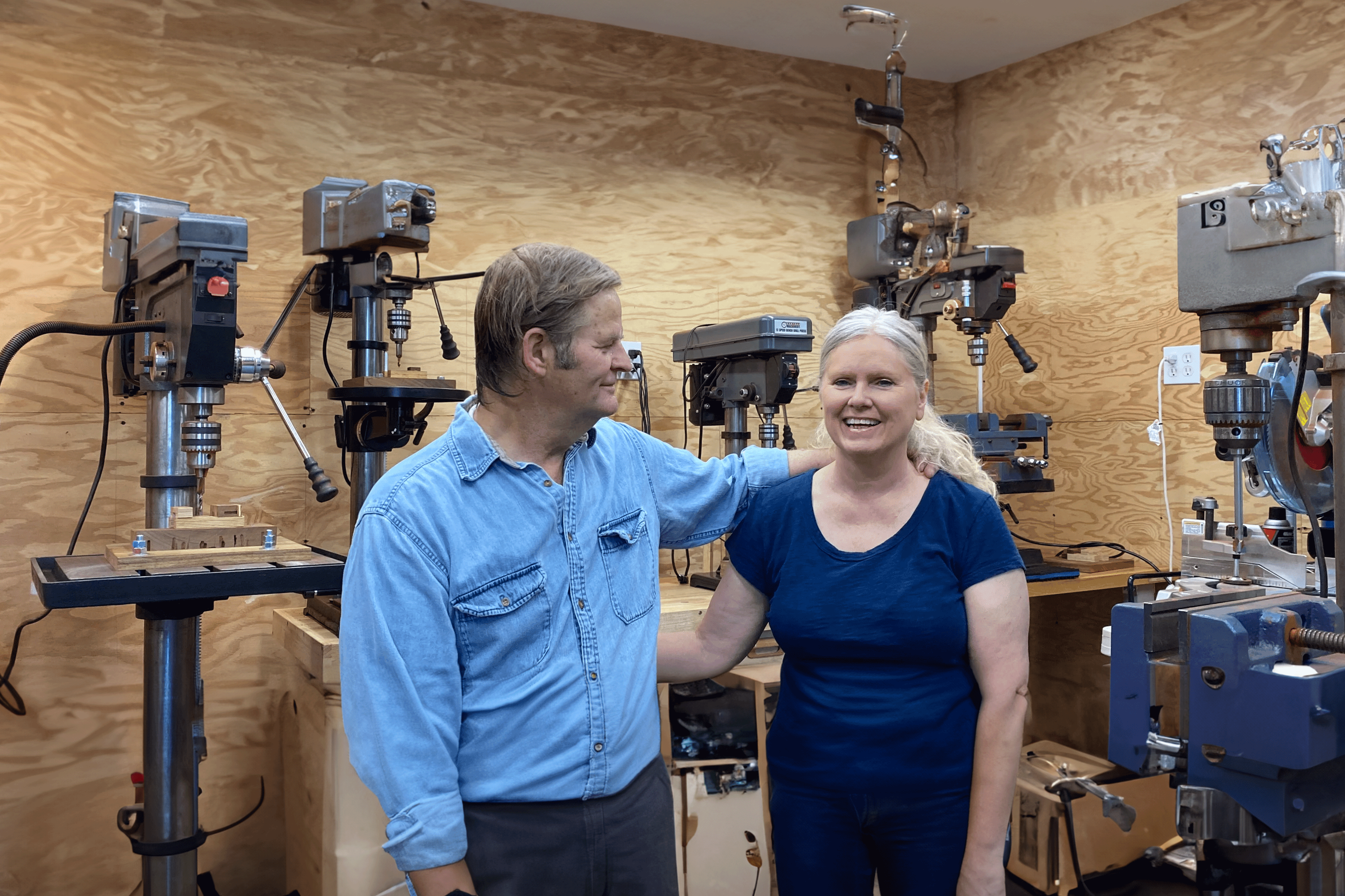

In the Workshop.

Vera and I went into the workshop to show you what it takes to make a Trekker handle. This procedure has evolved over the years. The drill press in the video is my newest one and is incredibly accurate. We used to throw away as many as two out of seven handles because the magnesium hole that we drill in the top was not vertical or near vertical. Now every handle is very close to perfect.

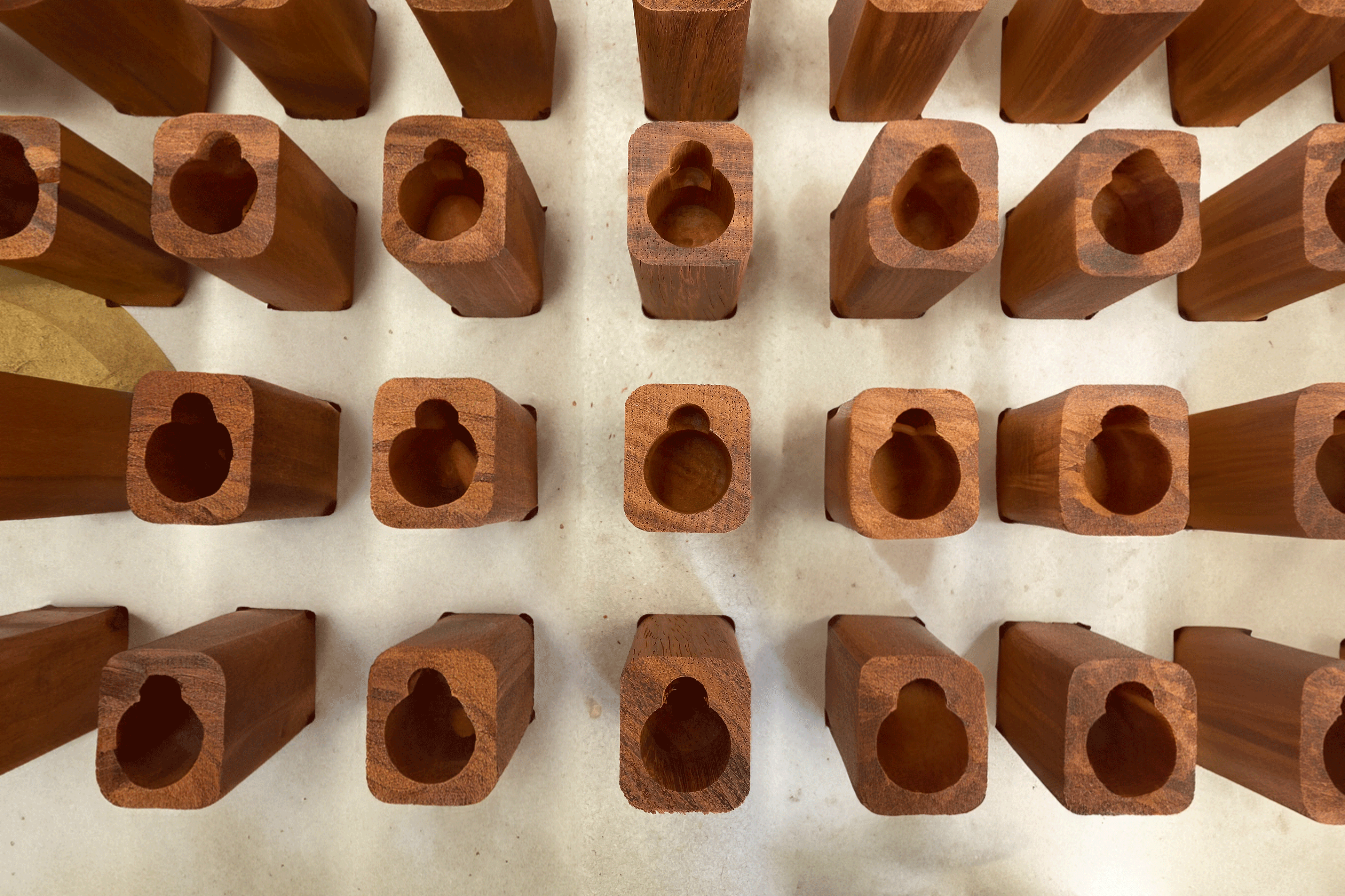

Actually, right up until March of 2019 the wood we received from the mill were 15 feet long by 1 inch and 1 1/8" inch rectangular rods. We then passed each rod 4 times through the router to take off the sharp edges and then over to the chop saw and cut to length.

Eventually our wood mill became curious and asked what we were doing. I told them - and they told me that they would round of the edges at no charge. 'Bout fell of my chair! That saved enormous time and effort and far more consistent than what I did with my router. Then later we negotiated for the mill to cut the wood to length. Where we would do one at a time they do 50.

We now spend all our week days making fire starters and most weekends go to shows to sell in person (and will again soon after the virus scare dies down).

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.